Last summer the Centers for Disease Control (CDC) reported more than 2,300 heat-related deaths nationwide—the steepest one-year spike in 45 years. For industrial health consultants like FACS, that sobering trend is an urgent conversation point with every client who pours concrete, lays pipe, welds, roofs, landscapes, farms, or performs other work in elevated temperatures during the summer months. Heat stress is a preventable hazard that can bring about serious harm to your employees and your business.

The Science of Heat Stress

When a job generates heat load (stress) faster than the body can dump that heat (strain), the internal thermostat misfires. Think of an engine with a plugged exhaust pipe—pressure climbs until the engine fails.

Three components tip the scale:

- Environment: air temperature, humidity, radiant heat, and air velocity (or lack of it).

- Workload: metabolic heat created by the body as it works to perform its duties

- Worker factors: hydration level, fitness, age, medications, alcohol use, acclimatization, and the insulating power of PPE.

At equilibrium, metabolic heat roughly equals heat lost through sweating, evaporation, and air movement. Tip any of the above components far enough and the body’s core temperature rises quickly, setting the stage for heat illness. Heavy exertion in mid-90s Fahrenheit air can dehydrate a laborer by two liters an hour—about a half-gallon. Losing that much fluid for three hours straight and your endurance and judgment unravel long before thirst sets in.

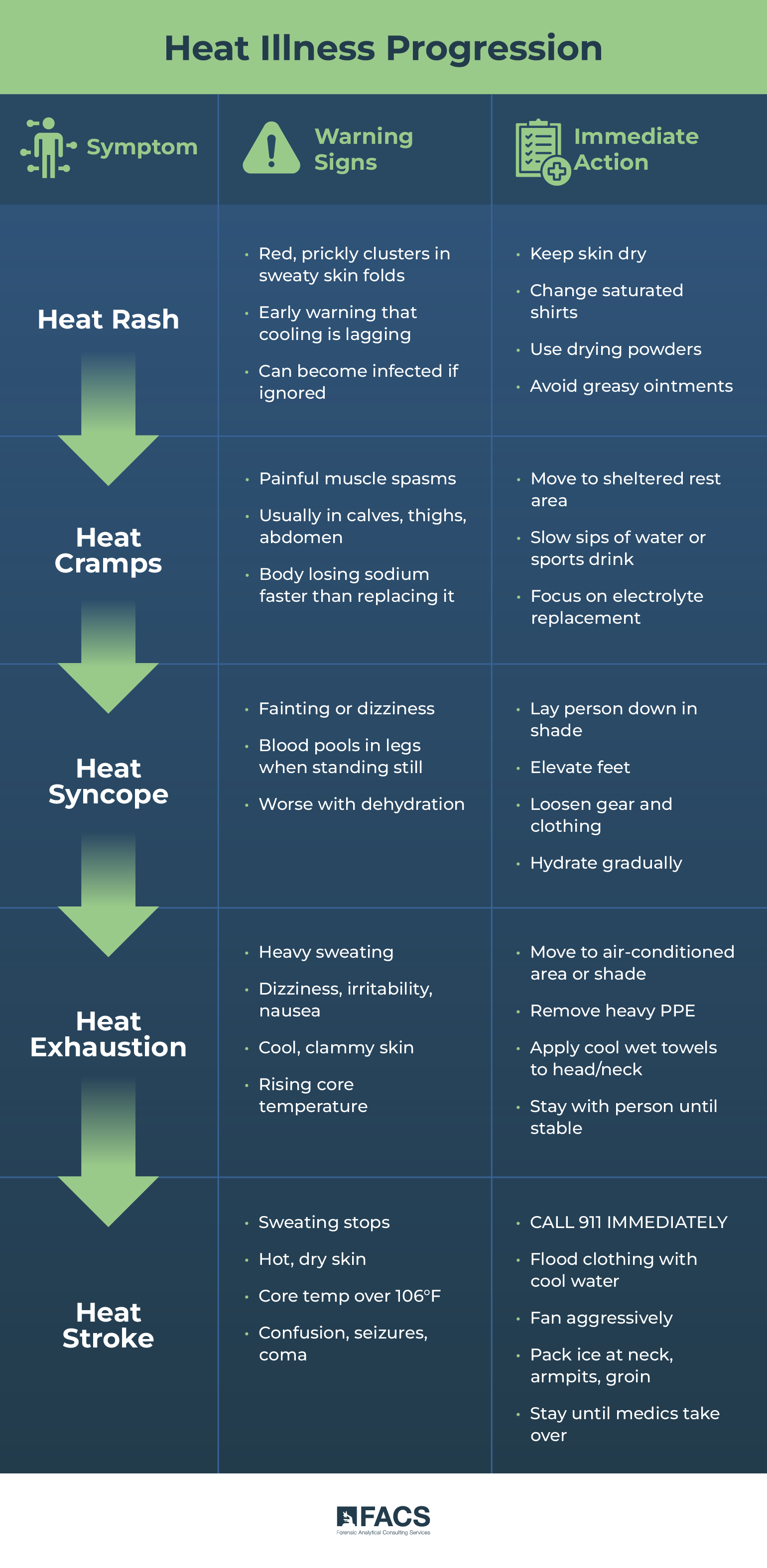

The Heat-Illness Ladder—Catch It Early

The Heat-Illness Ladder—Catch It Early

Heat Rash is the early warning light—red, prickly clusters in sweaty skin folds. Left unchecked it can infect, but more importantly it signals that body cooling is already lagging behind. Keep skin dry, swap out saturated shirts, dust with drying powders; skip greasy ointments that trap heat.

Heat Cramps —painful muscle spasms in the calves, thighs, even the abdomen. They strike workers who flush out sodium faster than they replace it. Treatment is simple: sheltered rest plus slow sips of a water or sports drink rich in electrolytes.

Heat Syncope is a fancy word for fainting. Blood pools in the legs when a worker stands motionless or bolts upright after stooping. Dehydration and poor acclimatization amplify the drop in blood pressure. Lay the person down in shade, elevate feet, loosen gear, and hydrate gradually.

Heat Exhaustion is the cliff edge. The employee sweats heavily, feels dizzy, irritable, nauseated; skin is cool and clammy but the body’s core temp climbs. Move them to an air-conditioned trailer or at least a shaded area, remove heavy PPE, apply cool wet towels to head and neck, and keep a buddy present until vitals stabilize or EMTs arrive.

Heat Stroke is the cliff. Sweating shuts down, skin turns hot and dry, core temperature rockets past 106 °F, and the central nervous system glitches—confusion, seizures, even coma. Every minute without active cooling risks permanent disability or death. Call 911, flood clothing with cool water, fan aggressively, pack ice at neck, armpits, and groin, and stay with the worker until medics take over.

Measuring the Invisible—Numbers that Drive Decisions

Using a standard thermometer to review heat risk is not the answer, that’s guessing, not managing. You need a method that captures humidity, air speed, and radiant load.

- Heat Index merges dry-bulb temperature with relative humidity to predict “feels-like” heat. It’s perfect for a lunch-room poster and a quick caution flag.

- WBGT (Wet-Bulb Globe Temperature) adds wind and radiant energy to the mix. One handheld meter delivers an objective number you can log by hour, shift, or location.

- The ACGIH Threshold-Limit Values (TLVs) translate WBGT into safe exposure times for acclimatized workers; an Action Limit is provided for new or returning staff.

- Work/Rest schedules—simple tables backed by NIOSH—convert WBGT plus workload (light, moderate, heavy) into duty cycles. Example: heavy manual work at 103 °F WBGT earns 20 minutes work / 40 minutes rest each hour.

If impermeable suits or FR coveralls trap heat, adjust the readings upward; plastic is a greenhouse that amplifies the heat impact.

Phone apps from OSHA and NIOSH put the math in every superintendent’s pocket, pinging hydration reminders and flagging extreme-heat warnings based on GPS coordinates.

Why Construction and Outdoor Trades Take the Hardest Hit

A paving crew can stand over fresh 300-degree asphalt, under hot summer sun, wearing double-layer fabrics. A rebar gang ties steel that reflects midday rays onto faces and necks like a tanning mirror. Roofers, miners, utility trench workers, agriculture hands—each adds its own twist: confined trenches, missing shade, diesel exhaust, or adrenaline-charged production goals that disguise early symptoms.

Combine high radiant heat, heavy metabolic demand, limited airflow, and brand-new hires who celebrated the weekend with beer and little sleep, and you have a perfect storm for heat stress illness.

Here’s a grim statistic worth repeating: Three out of four heat-fatalities occur in a worker’s first week on a hot site, when the body has not yet adapted. That single fact should reshape every onboarding plan.

Controls You Can Use to Combat Heat Stress

Engineering Controls: Improve cross-ventilation; install high-volume, low-speed fans when ambient air is cooler than skin; set porta-coolers at break stations; wrap ovens and generators with radiant shields; insulate steam lines; erect temporary shade screens at pour decks. Even small tweaks can cut radiant heat measurably.

Administrative Controls: Begin every hot season with a formal acclimatization plan: 20 percent of full duty on day one, adding 20 percent each day until the worker reaches 100 percent. Reschedule the heaviest tasks to pre-noon; rotate arduous jobs to equalize metabolic load; enforce cool-down breaks. A designated heat-safety lead should record WBGT, adjust work/rest cycles, and carry authority to call time-out.

Personal Protective Equipment: Is crucial when all else fails but unreliable alone. Ice vests, cooling towels, vented hard-hat liners, moisture-wicking base layers, and lighter-weight clothing blends can drop skin temperature enough to lengthen safe work bouts. Test new gear with a pilot pair of workers before you outfit an entire crew, and remember ice packs quit after an hour; schedule time to rechill.

Building a Heat-Illness Prevention Program That Lives and Breathes

A dusty binder on a shelf never saved a worker. Your Heat Illness Prevention Program (HIPP) should be visible, dynamic, and practical.

Post the plan. Water-Rest-Shade charts and urine-color hydration posters belong at the porta-john, the gang box, and the trailer door.

Brief daily. A two-minute tailgate that covers forecast, current WBGT, shift workload, and any extra controls trains situational awareness faster than a once-a-year slide deck.

Supply hydration. Cool water every 300 feet and electrolyte mixes on heat-alert days tell crews you value kidneys over schedule.

Drill first aid. Crews who are aware of heat illness symptoms are able to treat heat illness faster and call for help sooner. Assign a buddy system.

Audit and correct. Log WBGT regularly, pair readings with crew lists, and review any incident for gaps in acclimatization, PPE, supervision, or engineering controls.

Stay legal. OSHA’s Heat-Hazard National Emphasis Program is already ticketing job sites when the heat index tops 80 °F. A federal heat standard is moving through rulemaking; states like California, Oregon, and Washington enforce even stricter rules.

Finish Strong—A Five-Step Field Checklist

- Pull last summer’s incident logs and flag every heat-related entry.

- Inventory equipment: WBGT meter, shade structures, coolers, PPE

- Write or dust off your HIIPP and acclimatization schedule and hand it to every foreman.

- Install hydration and first-aid posters where eyes linger—porta-johns, lunch trucks, tool rooms.

- Run a tabletop drill: “It’s 106 °F WBGT at 2 p.m.; laborer collapses on deck—what next?”

The cost of prevention is measured in minutes and gallons; the cost of failure is measured in lives and lawsuits. Measure the heat, write the plan, train the people, and stand ready with water, rest, and shade. The sun is predictable. Let your prevention be just as relentless.

For more information, watch the FACS webinar on heat stress here. And for quick help developing your Heat Illness Prevention Program, call FACS at (888) 711-9998 or contact us online here.